For a large facility, keeping HVAC systems in tip-top shape is a huge challenge. Although staff may notice failures of those heating, ventilation, and air conditioning systems soon enough, it may take days or even weeks before an on-site technician can locate the source of the problem. This is especially problematic for large medical centers where these HVAC systems are bringing in fresh air that can help prevent the spread of infectious disease.

Santagostino, a network of 35 medical centers throughout Italy, was losing the battle when it came to monitoring and maintaining their HVAC systems, so they decided to do something about the problem. After looking into existing, commercial solutions that might help, they found them to be too expensive and inflexible. This led them to build their own homegrown solution with Arduino boards and Edge Impulse that is capable of recognizing when each of their HVAC units is on, and also of watching for abnormal operations, such that problems can be fixed early, before they become more serious.

An Arduino Nano RP2040 Connect was chosen because it comes with a Wi-Fi radio and high-quality accelerometer built in, so no additional hardware was needed. Additionally, the board is open source and simple to program, and the onboard Raspberry Pi RP2040 microcontroller provides more than enough processing power for the task. These characteristics allowed the team at Santagostino to develop their own device, and the low price tag enabled them to deploy it widely, for a fraction of what a commercial solution would have cost.

The idea behind the solution is to attach an Arduino to each HVAC system, and program it to periodically wake up and collect accelerometer data, which reveals the vibratory patterns of the system. The team believed that this data would be able to reveal whether or not a system was running, and also if it was operating in some abnormal way that would indicate that it needs to be serviced. How exactly vibrations relate to different operating states is not obvious, however, so Santagostino turned to Edge Impulse to help them design a machine learning model capable of classifying vibratory patterns.

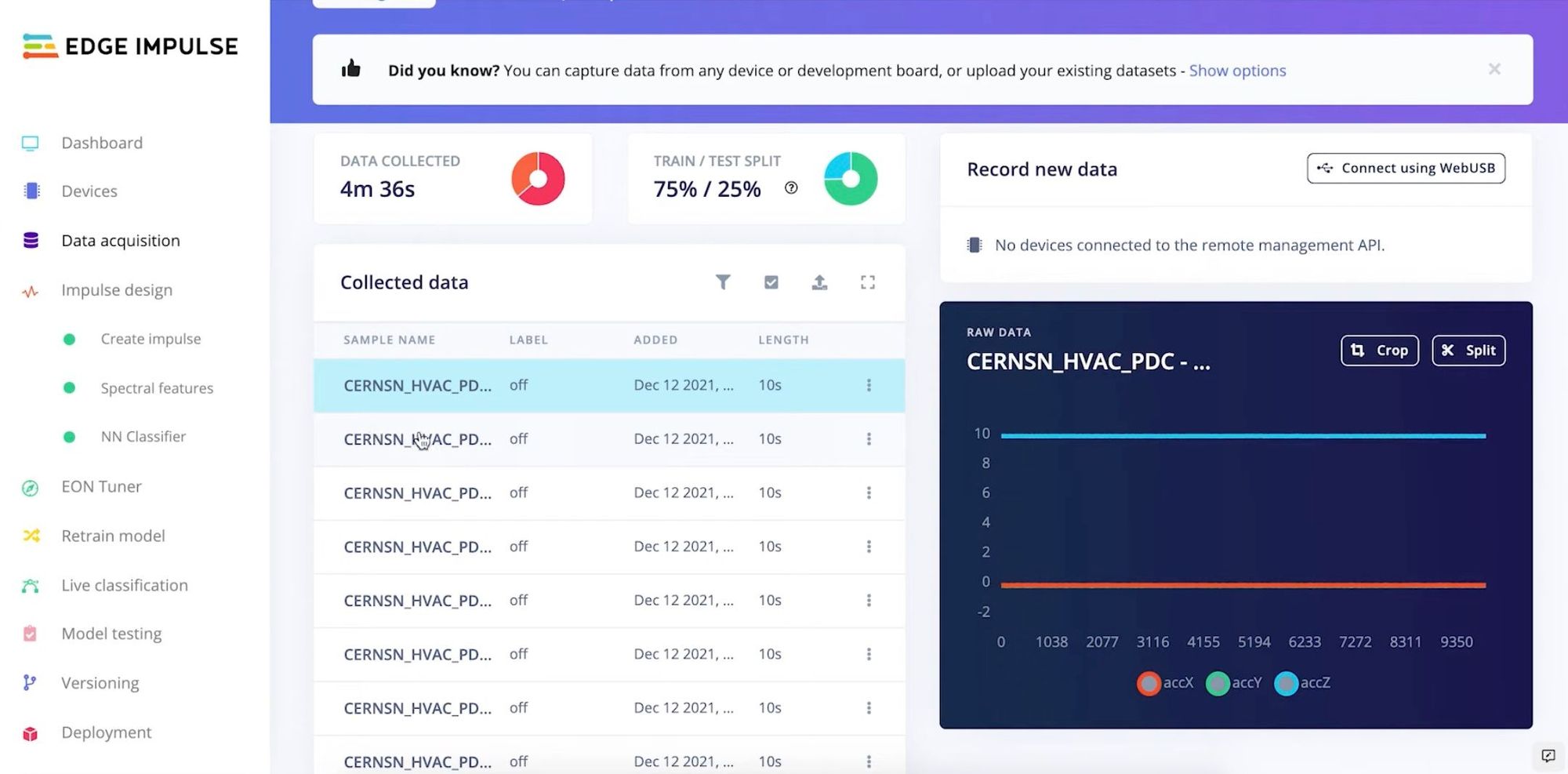

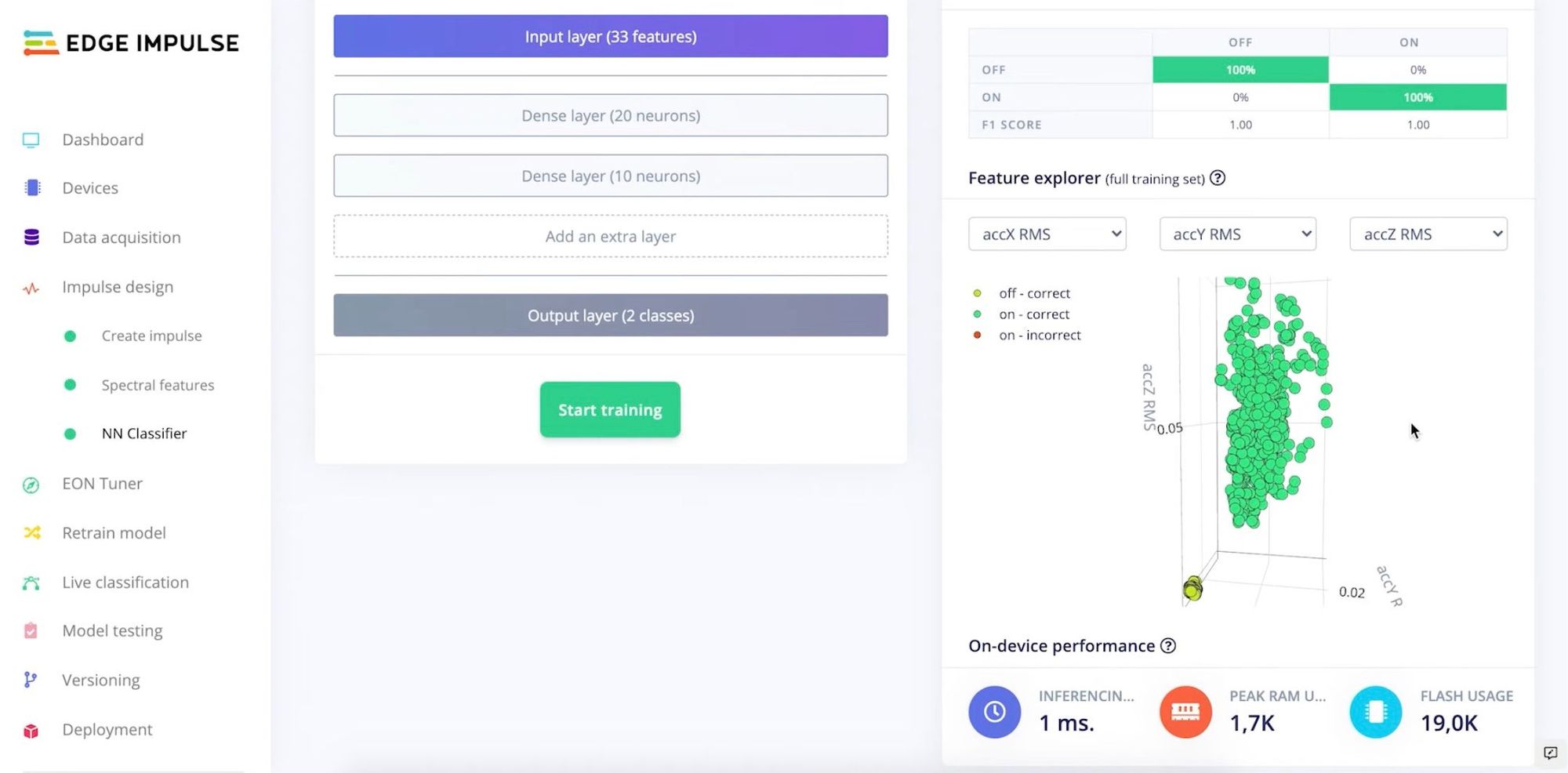

A batch of accelerometer data was first collected, then uploaded to Edge Impulse. Next, an impulse was created to preprocess the input data and feed it into a neural network classifier. The model was then trained with the examples found in the collected training data before being deployed to the Arduino, where it can run on-device.

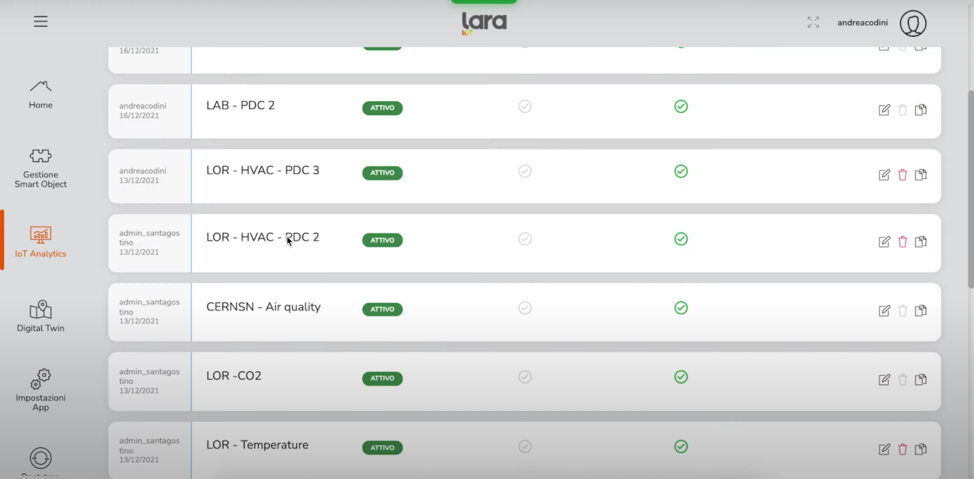

Since the device can simply be affixed to the outside of an HVAC system to collect vibration data, it required no modifications — or voided warranties — for the monitored systems. The periodic inferences from the neural network are wirelessly transmitted to a centralized dashboard application that Santagostino can use to gain insights across their entire network of medical centers.

Since implementing their solution, they have been able to locate failed systems to expedite repairs, and also to save energy by identifying systems that were unnecessarily running during off-hours and holidays.

By using off-the-shelf, open source hardware as well as eliminating the complexities of machine learning with Edge impulse, Santagostino was able to easily build a completely customized solution to their problem, and avoid expensive, proprietary solutions. Their story is a fantastic reminder that benefiting from machine learning at your own organization does not need to be expensive or overly complicated. Head on over to Arduino’s case study to learn more about Santagostino’s success.